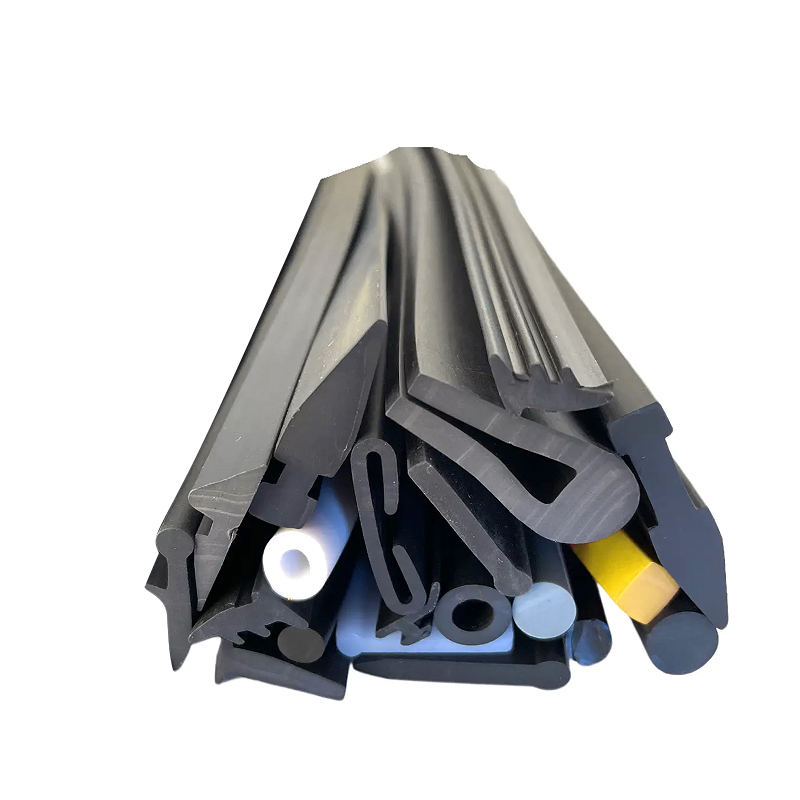

Shenzhen Xinhaiwang Technology Co., Ltd. supplies two main kinds of extruded strips: chemical resistant ones and the more everyday, general type. Though both look similar at a glance, their inner chemistry and intended jobs are miles apart.

The chemical-resistant strips use top-shelf compounds like Viton FKM, FFKM, or tough NBR rubber. Those materials laugh off concentrated acids, sharp alkalis, oils, and most solvents, so youPointer de risk them around industrial pipes or chemical tanks. The general-purpose strips, meanwhile, stick to EPDM or silicone. They seal doors, windows, and panels just fine, stand up to rain and sun, and bend easily, but they quit when the chemicals turn nasty.

Picking the right strip isn t rocket science if you know the environment. Go heavy-duty for places where corrosion is more than a rumor. That hand-off between specialty and everyday rubber can save huge money down the road. Automakers, hospital machinists, and assembly plants swear by the wear-proof version because it s one piece that won t strand the whole project.

Every client who picks our gear gets peace of mind. They can run their daily tasks without fretting over wear and tear.