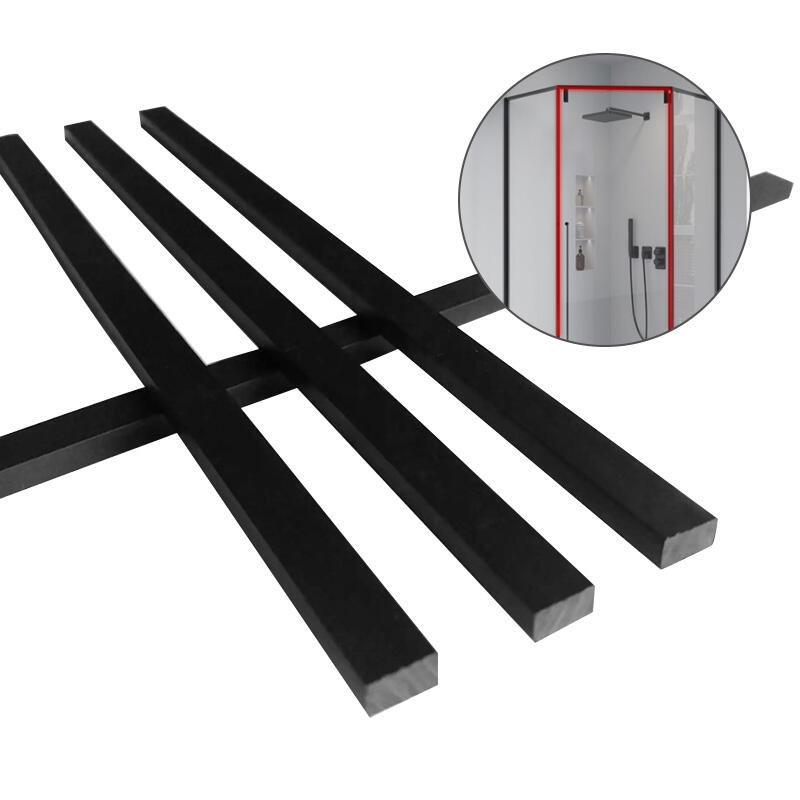

Silicone Foam Strips are materials with outstanding performance in multiple applications that are not found elsewhere. In contrast to Open Cell Foam which has a tendency to soak up water, Silicone Foam remains intact in wet conditions and thus can be used for sealing, cushioning and insulation purposes. These strips are used in particular for automotive, medical and household items where strength and reliability are essential. These products are manufactured through advanced production methods, and comprehensive quality control systems that ensure Silicone Foam Strips’ performance and safety requirements are adequately addressed.