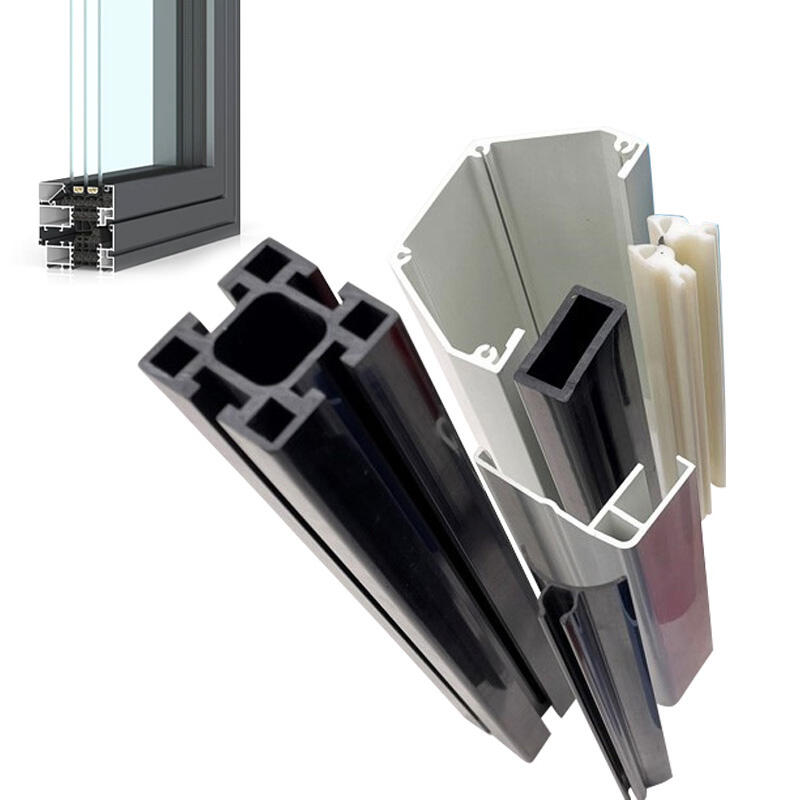

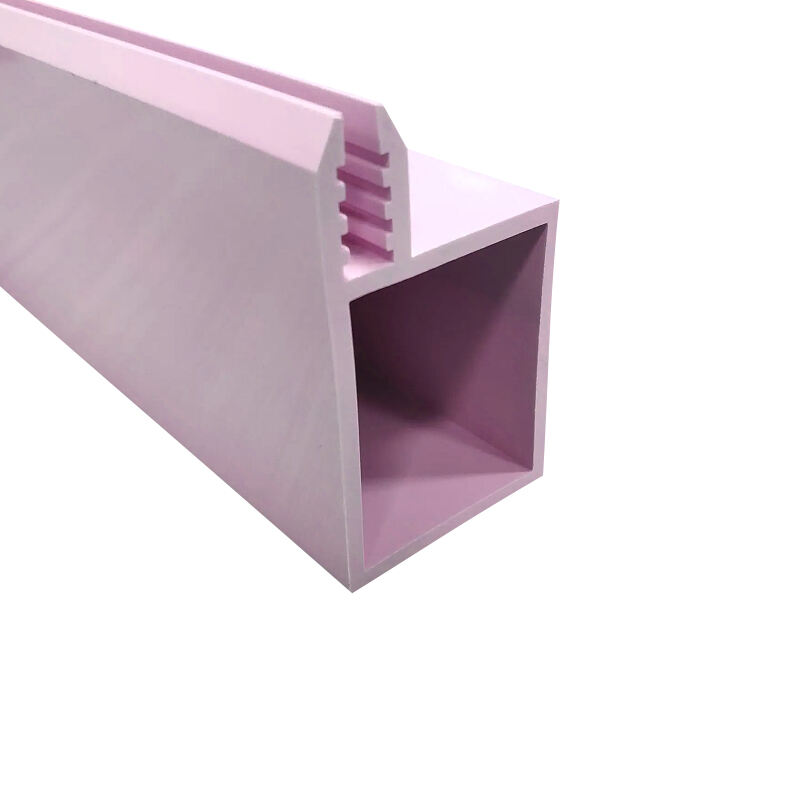

Today, strip seals are the most modern solution in sealing technology and have a range of advantages compared to weather stripping. Their ingenuity in design and materials helps improve strength, flexibility, energy efficiency and extends their use across more industries. Strip seals provide a dependable seal against the elements in places as diverse as; automotive manufacturing, the production of medical devices, and in the household. At ShenZhen XinHaiWang Technology Co., Ltd. we also design and fabricate strip seals that are specifically customized for the needs of our clients in order to achieve maximum satisfaction and success.