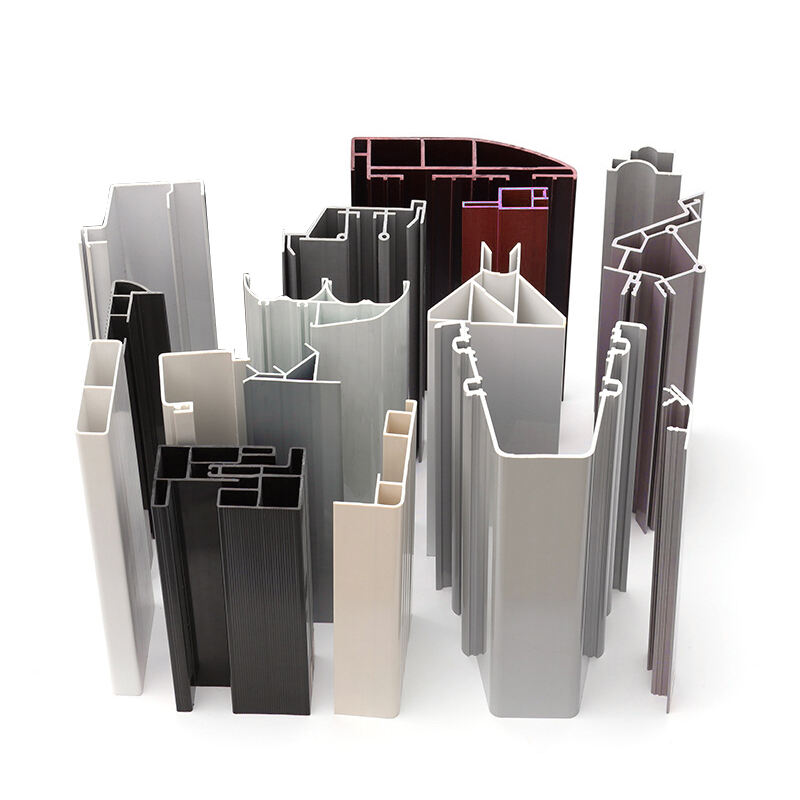

تعيش العديد من الصناعات أهمية مميزة لاستخدام الشرائح المُستخرجة، وهذه الأهمية ستستمر بالنمو في منتجات يومية مختلفة. تقدم هذه الشرائح، التي يتم تصنيعها عبر عمليات الاستخراج، قوة وتماسكًا يسمحان باستخدامها في تطبيقات صناعية متعددة في مجالات البناء والسيارات والمنتجات الاستهلاكية. في هذا المقال، سنحلل الشرائح المستخرجة من حيث متانتها وكفاءتها في أداء وظائف مختلفة، كما سنناقش فوائدها والتطورات الحديثة في القطاع. أما بالنسبة لعملية الاستخراج، فهي إجراء يتم فيه دفع المادة عبر قالب للحصول على جسم طويل له شكل معين. يعتبر هذا النهج مفيدًا بشكل خاص في إنشاء الشرائح من مواد مثل المعدن والبلاستيك والمطاط. تتميز الخصائص الميكانيكية للشرائح المستخرجة بتفوقها، وهو أمر مهم خاصة في الحالات التي تكون فيها القوة والعمر الافتراضي الأمثل حاسمة. اليوم، تُفضل الشرائح المستخرجة في الصناعات التي تحتاج إلى مواد ذات جودة عالية، حيث يمكنها تحمل الظروف القاسية ولديها مقاومة عالية للتآكل. تعتبر مرونة الشرائح المستخرجة واحدة من العوامل الأكثر أهمية، مما يمنح الشركات المصنعة ميزة إضافية. يمكن للمصنعين تعديل أي أو كل من الحجم أو الشكل أو خصائص المرونة. توفر هذه المرونة للشركات إمكانية إنشاء وتصميم منتجات جديدة تمامًا عن غيرها في السوق. على سبيل المثال، في التطبيقات السيارات، تُستخدم الشرائح المستخرجة ذات الحبات كأختام مناخية وكمزخرفات تتطلب أداءً عاليًا. عند استخدام الشرائح المستخرجة كمكونات للمنتج، يكون هناك فائدة إضافية تتمثل في تحسين مستوى الأداء وزيادة عمر السيارة. بالإضافة إلى الجوانب الوظيفية، تدعم الشرائح المستخرجة المبادرات المتعلقة بالاستدامة. يتم الآن دمج المواد القابلة لإعادة التدوير في عملية الاستخراج من قبل المزيد من المصنعين لتقليل النفايات والتأثير البيئي. وهذا يجيب على الاتجاه المتزايد بين المستهلكين بشأن الوعي البيئي، مما يجعل الشرائح المستخرجة أكثر جاذبية للشركات التي تريد تحسين صورتها البيئية. أيضًا، الخطوات المبسطة في عملية الاستخراج تجعل من الممكن توفير الطاقة، وهي ميزة أخرى كبيرة لتقليل البصمة الكربونية. لا تتوقف نطاقات استخدام الشرائح المستخرجة عند الاستخدامات التقليدية. خلال السنوات الأخيرة، بدأت مجالات مثل الإلكترونيات والأجهزة الطبية في استخدام هذه المواد بسبب ميزاتها الفريدة. على سبيل المثال، تُستخدم الشرائح المستخرجة في تطوير أغلفة وحواف وأجزاء أخرى دقيقة وقوية. مع تقدم التكنولوجيا، يجب أن نتوقع استخدامات جديدة وأفضل للشرائح المستخرجة، مما سيزيد من نمو هذا السوق. على المدى القصير، يمتلك سوق الشرائح المستخرجة آفاقًا واعدة مدفوعة بالتقدم في مواد التصنيع والتكنولوجيا. وبشكل أكثر تحديدًا، مع تطور التكنولوجيا، سيزداد الطلب على هذه المنتجات عالية الأداء والدائمة.

EN

EN