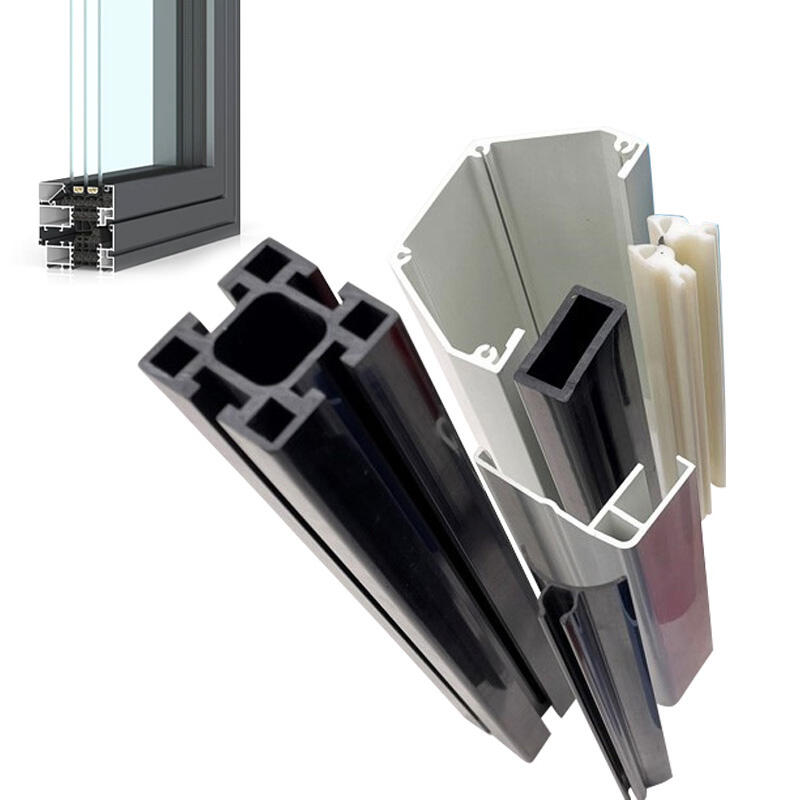

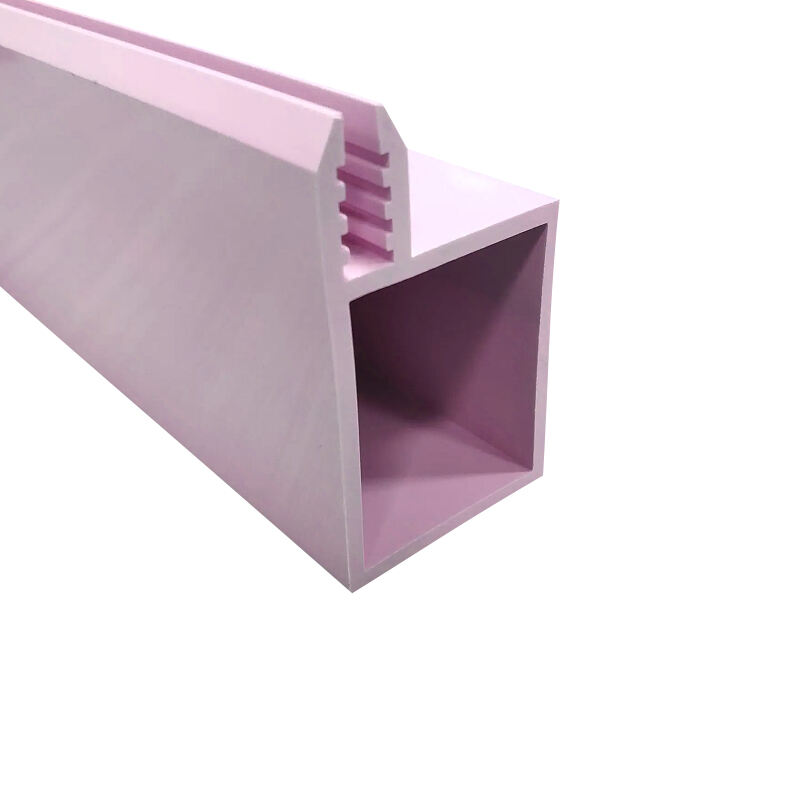

As one weighs sealing options, the decision to use strip seals or self-adhesive seals can determine the effectiveness and lifespan of one’s products. Strip seals are usually composed of durable rubber and polymer plastics while self-adhesive seals attach to a sticky surface which may lose its luster with time. Our expertise in precision mold technology ensures that our strip seals provide the best sealing properties, performing perfectly in automotive, medical, industrial machinery and other applications. In case of strip seals, customers will have the advantage of increased robustness, more personalization options and decreased operational costs over time.