Τα ελαστικά παρεμβύσματα είναι σημαντικά στο σχεδιασμό προηγμένων μηχανημάτων. ενισχύουν την αποτελεσματικότητα, τη συνέπεια και την ασφάλεια. Καθώς όλο και περισσότερες Βιομηχανίες αρχίζουν να ανθίζουν, υπάρχει συνεχής ανάγκη για παρεμβύσματα μεταξύ πολλών άλλων εξαρτημάτων. Αυτό το άρθρο διερευνά την έννοια των ελαστικών παρεμβυσμάτων, την ποικιλομορφία τους όσον αφορά τους τύπους και τις χρήσεις και τι τους επιφυλάσσει το μέλλον όσον αφορά την ανάπτυξη.

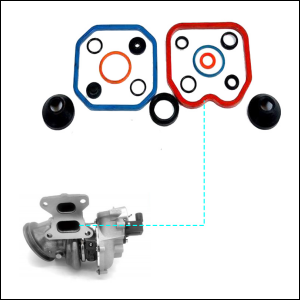

Οι υδραυλικές εφαρμογές σε δύσκολα περιβάλλοντα όπως η στεγανοποίηση υγρού ή αερίου σε μέτρια πίεση και θερμοκρασία απαιτούν ελαστικά παρεμβύσματα. Προσφέρουν στεγανοποίηση συμπίεσης που βοηθά στην εξάλειψη τυχόν κενών που μπορεί να υπάρχουν στα εξαρτήματα. Αυτό είναι ζωτικής σημασίας για μηχανήματα όπου η πίεση και η θερμοκρασία σε μια διαδικασία αλλάζουν συχνά, έτσι ώστε να μην υπάρχουν διαρροές που θα μπορούσαν να οδηγήσουν σε αστοχία του μηχανήματος και ζητήματα ασφάλειας. Χρησιμοποιείται μια ποικιλία ελαστικών παρεμβυσμάτων σε όλες τις πτυχές, συμπεριλαμβανομένων — δακτυλίων O, επίπεδες φλάντζες και ακόμη και ειδικά κατασκευασμένα παρεμβύσματα. Κάθε τύπος φλάντζας έχει ξεχωριστές εφαρμογές που εξαρτώνται από τις ατομικές απαιτήσεις του μηχανήματος.

Το κύριο πλεονέκτημα των ελαστικών παρεμβυσμάτων είναι οι ποικίλες ιδιότητές τους και το γεγονός ότι μπορούν να κατασκευαστούν από διαφορετικά υλικά από καουτσούκ όπως νιτρίλιο, EPDM και σιλικόνη που είναι κατάλληλα για διαφορετικές εφαρμογές. Για παράδειγμα, τα παρεμβύσματα σιλικόνης θα πρέπει να χρησιμοποιούνται για εφαρμογές υψηλής θερμοκρασίας. Τα παρεμβύσματα νιτριλίου από την άλλη είναι κατάλληλα για χρήση σε λάδια και καύσιμα λόγω της αντοχής τους στα πετρελαϊκά προϊόντα. Αυτό σημαίνει ότι οι μηχανικοί έχουν την επιλογή να επιλέξουν το πιο κατάλληλο υλικό φλάντζας, βελτιστοποιώντας έτσι την απόδοση και τη διάρκεια ζωής του εξοπλισμού που χρησιμοποιείται.

Επιπλέον, λόγω της προόδου της τεχνολογίας, η διαδικασία κατασκευής ελαστικών παρεμβυσμάτων έχει βελτιώσει σημαντικά τα παρεμβύσματα. Η χρήση χύτευσης ακριβείας και κατεργασίας CNC, μεταξύ άλλων διαδικασιών, κατέστησε δυνατή τη σχεδίαση και την παραγωγή παρεμβυσμάτων που είναι πολύπλοκα σε σχήμα και διαστάσεις. Αυτό το είδος ακρίβειας όχι μόνο βελτιώνει την καλή απόδοση της σφράγισης, αλλά διασφαλίζει επίσης ότι τα απόβλητα παραγωγής μειώνονται κατά τη διάρκεια της διαδικασίας, καθιστώντας έτσι δυνατή τη βιώσιμη παραγωγή. Καθώς υπάρχουν όλο και περισσότερες βιομηχανίες που στρέφουν την εστίασή τους στη βιωσιμότητα, υπάρχει μια αυξανόμενη τάση χρήσης εναλλακτικών υλικών που είναι πιο φιλικά προς το περιβάλλον στην παραγωγή παρεμβυσμάτων.

Εκτός από τον σκοπό λειτουργίας τους, τα ελαστικά παρεμβύσματα είναι επίσης ζωτικής σημασίας για την εκπλήρωση διαφορετικών κανονισμών, προτύπων και απαιτήσεων ασφαλείας. Ωστόσο, ορισμένες βιομηχανίες παρακολουθούνται στενά και τηρούν τα καθορισμένα πρότυπα αξιοπιστίας και απόδοσης των διαφόρων εξαρτημάτων που χρησιμοποιούνται στις μηχανές. Οι τεχνικές οδηγίες και οι απαιτήσεις υλικών για τα ελαστικά παρεμβύσματα, εάν τηρηθούν σωστά, θα βοηθήσουν τις εταιρείες να αποφύγουν την επιβολή κυρώσεων βελτιώνοντας παράλληλα τη θέση τους στην αγορά.

Όσον αφορά τα οφέλη από τη χρήση ελαστικών παρεμβυσμάτων στο σχεδιασμό σύγχρονων συσκευών, είναι επίσης πολλά υποσχόμενα. Με τις τάσεις αυτοματισμού και έξυπνης κατασκευής να διαμορφώνονται, αναμένεται ότι τα παρεμβύσματα υψηλής ποιότητας και ακριβείας θα είναι σε ζήτηση. Η ανάπτυξη προηγμένων τεχνολογιών στην επιστήμη των υλικών θα έχει ως αποτέλεσμα την εισαγωγή περισσότερων ελαστικών υλικών που έχουν ακόμη πιο ανθεκτικές ιδιότητες σε ακραίες συνθήκες και επεκτείνοντας έτσι την εφαρμογή των καουτσούκ. Επιπλέον, η ανάπτυξη εξοπλισμού IoT σε συσκευές μπορεί να συμβάλει στην προγνωστική συντήρηση στο μέλλον όπου η κατάσταση των ελαστικών παρεμβυσμάτων μπορεί να παρακολουθείται και να αλλάζει όταν χρειάζεται, κάτι που θα συμβάλει στη μείωση του χρόνου διακοπής λειτουργίας.

Συνοψίζοντας, τα ελαστικά παρεμβύσματα είναι πολύ ζωτικής σημασίας για τη λειτουργία και την ασφάλεια των σύγχρονων μηχανημάτων. Η αποτελεσματικότητά τους, η ανάπτυξη και η βελτίωση των διαδικασιών παραγωγής τους θα τα καταστήσει πολύ σημαντικές παραμέτρους σε πολλούς τομείς της οικονομίας. Ωστόσο, καθώς προσβλέπουμε, θα είναι ζωτικής σημασίας τόσο για τους κατασκευαστές όσο και για τους μηχανικούς να παρακολουθούν τις τάσεις και τις καινοτομίες σε έναν συγκεκριμένο κλάδο. Διαφορετικά, δεν θα είναι σε θέση να ανταποκριθούν στην ανάπτυξη της αγοράς στο μέλλον.

EN

EN