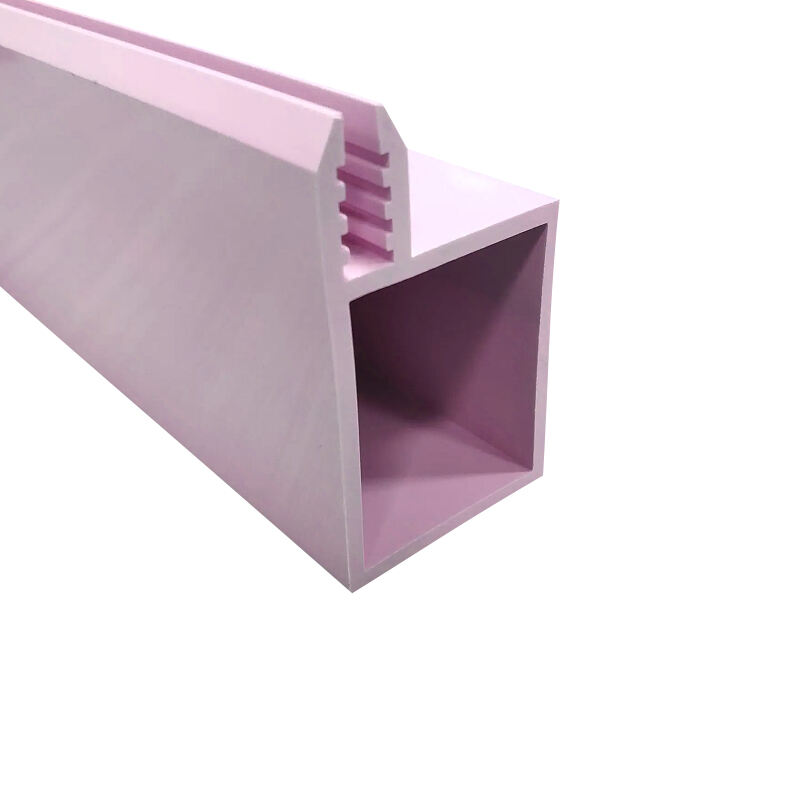

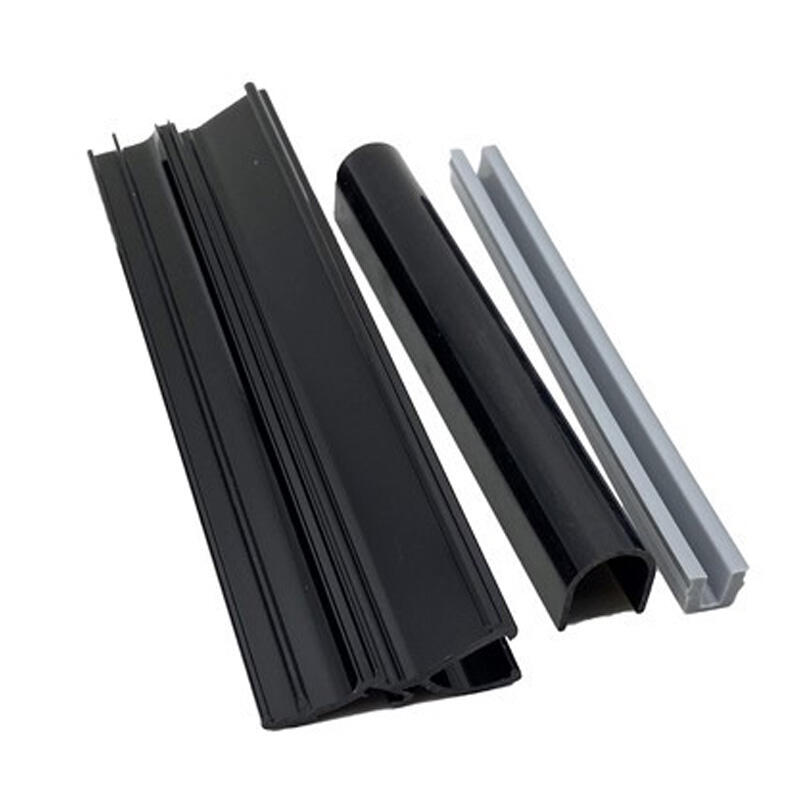

Strip seals offer a number of advantages when used in one or a number of applications than a normal rubber seal. First off, strip seals are made from certain materials and have an inclination that enables to them withstand some pressures and factors in their use environment making them excellent for hard cases. Such as, there are a lot of industries that use strip seals, including the automotive and rail transportation industries, which always count on strip seals to meet their needs. When they adopt the use of strip seals, enterprises can provide sealing solutions that meet clients tough sealing specifications and promote business operational effectiveness and safety.